Many companies also find prototype testing an invaluable starting point in their development process since it allows them to check whether their ideas are feasible and their end products will be easy to use. In recent years, the testing equipment utilized for prototypes has been transformed significantly from early manual techniques to modeled interfaces for realistic behavior. This evolution has not only helped to make the testing more efficient but also helped to make the quality of the product better before coming to the market.

Early Physical Prototyping

Regarding testing designs, the first concept of prototype testing involved materials such as clay, wood, or metal to generate models. Such prototypes could be developed from wood, metal, and even paper, cloth, or other materials by master artisans or engineers to resemble the final product in shape and utility. Nevertheless, these physical prototypes were only partial. They took a long time and were expensive to make, and if modifications were needed, it was started all over from the beginning.

Although these form and function models provided a good sense of the form and function during the early concept development, the drawback is that it took a lot of work to incorporate the user feedback and implement the changes quickly. This most often led to longer development cycles and higher costs than otherwise would have been the case.

The Shift to Digital Prototyping

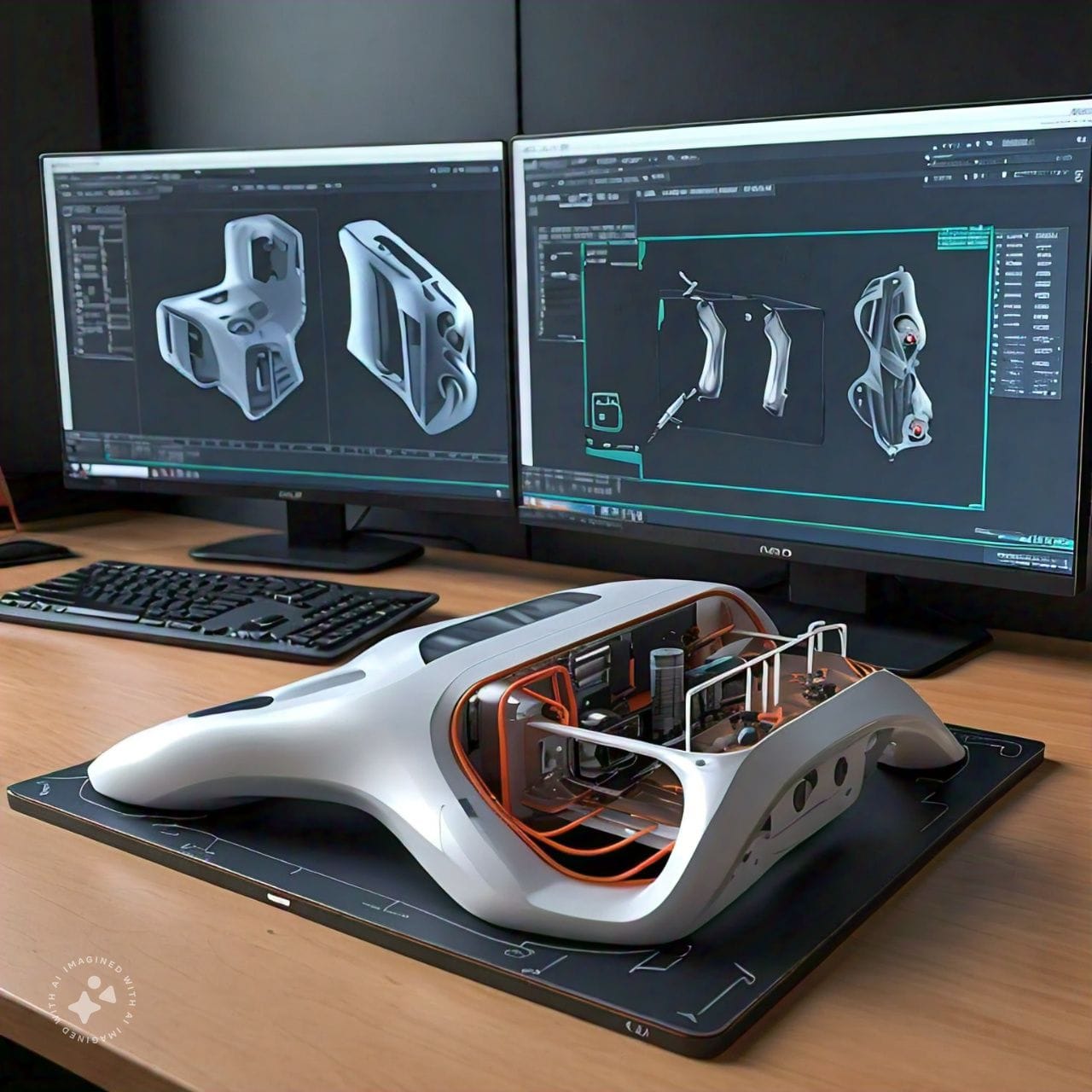

The last development of prototype testing came with the beginning of the CAD (Computer Aided Design) system in the late twentieth century. CAD software enabled designers and engineers to make precise models of ideas regarding the finalized products. These virtual prototypes are easy to manipulate, modify, and distribute in cross-functional teams compared to traditional ones.

Digital prototyping entailed that through modeling and simulations, organizations could test physical attributes, measurements, and the usability of actual products. This made it possible to see where a design may be weak and where changes can be made instantly without using physical material. It also paved the way for more collaborative design efforts, as digital files could be shared and modified by different stakeholders.

The Emergence of User-Centric Testing Tools

With a shift in the focus of manufacturing and increased complexity of the items being developed, testing of prototypes started to encompass the user experience. These tools also created interactive prototypes about how end-consumers would use the product. For example, designers could now build mock link interfaces for users to click through, which could give true-to-life feedback on how functional and user-friendly a product would be.

They were scored on actual feasibility or how users engaged with the product; this transition to UX testing tools let firms shift from merely physical functionality appraisals. Prototyping and other UX designing instruments, such as the wireframing of layouts and mockup applications, enable designers to present interfaces and examine the users’ reactions to slate interfaces before development. It enabled the development of products with enhanced functionality and utility that are adequate to the requirements and anticipation of the users.

New Trend in Prototype Testing Tools

More recently, innovations in other fields like artificial intelligence and machine learning, along with various enhancements of prototype testing tools such as virtual reality, have also emerged. Today’s tools allow for quick prototyping, immediate feedback, or even feedback that might predict problems that might occur.

3D printing has also impacted physical prototyping by enabling firms to make accurate prototypes within a relatively short span and at low costs. Moreover, augmented reality (AR) and virtual reality (VR) will allow the designer to experience, examine, and manipulate the interaction between the designer and the product as a tangible object. That has enhanced the possibility of testing products in realistic conditions without having physical counterparts.

Additionally, current technology advancements in cloud solutions enable the international team to work on a prototype and receive continuous, prompt feedback simultaneously. Not only that, the exporting process has become faster, and it has also contributed to the creation of better products to suit different markets.

Conclusion

A significant impact of prototype testing tools is that they have changed how companies design products. While the tools available have gone from hand-made physical models to accurate digital simulations, some advantages of modern design tools include a combination of both speed or iteration and accuracy, emphasis on the actual use of the product, etc. There are indications that prototype testing is destined for even further positive evolution as the rate continues to grow to enhance production and provide optimal quality goods to meet users’ needs and standards as soon as possible.