High-pressure die casting is a common manufacturing process for creating precise, durable, and complex metal parts. It involves injecting molten metal into a mold at high pressure, ensuring exceptional detail and strength. Manufacturers choose this method for its efficiency, speed, and ability to produce high-quality components with reduced waste. Whether for automotive, aerospace, or consumer products, high-pressure die casting offers unmatched reliability and performance.

This comprehensive guide explains high-pressure die casting, why it is commonly used, and its possible applications.

What Is High Pressure Die Casting?

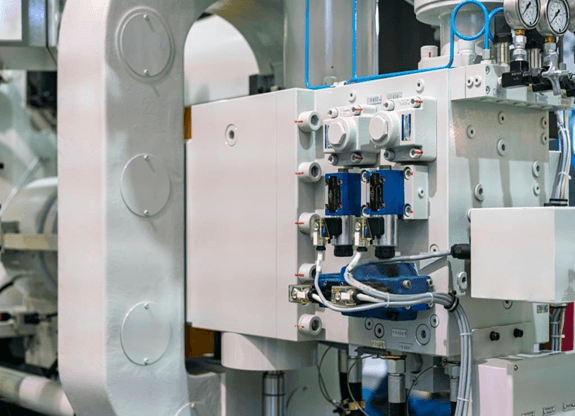

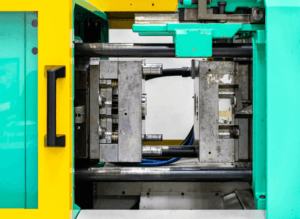

High-pressure die casting forces molten metal under pressure into a sealed mould hole. A strong compressive force (a real die fitted in a hydraulic machine) maintains the die in position until the metal solidifies.

Following solidification, the die is freed, opened, and the metal is extracted. After removal, the mould cavity is resealed for the next cycle. Molten metal is injected into the cavity in a fraction of a second (often under 100 ms). Once the die cavity is filled, extremely high pressure (typically over 1000 bar) is applied to a molten metal true injection plunger. This phase is known as intensification.

This pressure compresses any gases trapped in the metal (during particularly fast and turbulent cavity filling). It feeds more metal into the mould to partially compensate for the metal’s shrinkage during solidification.

Why Use High Pressure Die Casting?

Due to its unique benefits, high-pressure die casting is a go-to solution for manufacturers. Let’s take a closer look at why this process is so commonly used:

Precision and Accuracy

High-pressure die casting creates parts with exceptional dimensional accuracy. This process forces molten metal into a mold under high pressure, ensuring every mold detail is replicated. It’s perfect for complex designs or components that demand tight tolerances. As a result, it minimizes or even eliminates the need for post-machining, saving time and reducing costs.

High Production Speed

This process is incredibly fast compared to other casting methods. Once the die is prepared, it can produce thousands of parts in a single production run. The quick solidification of molten metal under high pressure shortens cycle times, allowing manufacturers to meet tight deadlines or handle large-scale production efficiently.

Excellent Surface Finish

Parts produced through high-pressure die casting have a smooth and uniform surface finish. This reduces or eliminates the need for additional polishing, grinding, or other finishing processes. A high-quality finish also improves the product’s appearance and makes it easier to apply coatings or paints when required.

Material Versatility

High-pressure die casting is compatible with various metals, including aluminum, magnesium, and zinc. This versatility allows manufacturers to tailor their choice of material to specific application needs. Each material offers unique benefits:

- Aluminum: Lightweight, strong, and corrosion-resistant, making it ideal for automotive and aerospace applications.

- Magnesium: Lighter than aluminum yet strong, often used in electronics and lightweight structural components.

- Zinc: Durable and cost-effective, suitable for smaller, intricate parts.

Cost-Effectiveness

While the upfront tooling costs for creating dies can be significant, high-pressure die casting becomes highly economical for large production volumes. Once the tooling is in place, the process allows for rapid, repeatable production with minimal material waste. Over time, this lowers the per-unit cost, especially for mass production.

Durability and Strength

Parts produced through high-pressure die casting are known for their strength and durability. The rapid cooling under high pressure ensures a dense and uniform metal structure, which enhances the component’s mechanical properties. These parts are resistant to wear and can withstand harsh environments, making them suitable for demanding industries like automotive and industrial machinery.

Design Flexibility

High-pressure die casting enables the creation of complex shapes that would be hard or impossible to achieve with other methods. Features like thin walls, complex patterns, and integrated fasteners can be incorporated into the design without compromising structural integrity. This flexibility allows manufacturers to innovate and meet diverse product requirements.

Sustainability

This process produces minimal waste compared to other manufacturing methods. Excess material from casting can often be recycled, reducing raw material consumption and environmental impact. Additionally, die-cast parts’ durability means they have an increased lifespan, reducing the need for constant replacements and further supporting sustainability.