Air conditioning systems are crucial for maintaining comfortable indoor climates, especially in regions with extreme temperatures. A key component of these systems is the lineset, which plays an integral role in the efficiency and functionality of an air conditioner. The lineset consists of two separate lines: the suction and liquid lines. We will explore how these lines contribute to an air conditioning system’s overall performance, installation requirements, and maintenance needs. Understanding the importance of AC lineset helps ensure optimal operation and longevity of the cooling system.

Understanding AC Linesets

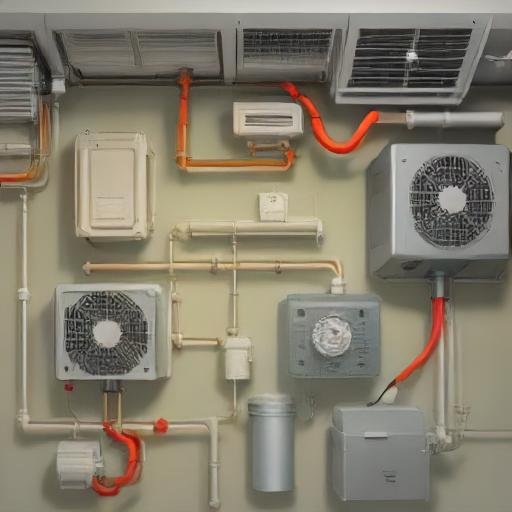

The lineset in an air conditioning system is essential for the transfer of refrigerant between the indoor and outdoor units. It consists of two distinct lines: the suction line and the liquid line. The suction line carries refrigerant in a gaseous state from the evaporator coil inside the building to the compressor outside. This line is typically insulated to prevent condensation and ensure efficient cooling. On the other hand, the liquid line transports refrigerant in a liquid state from the condenser coil to the expansion valve or metering device. Proper functioning of these lines ensures that the refrigerant cycle is completed efficiently, facilitating effective cooling of indoor spaces.

Installation Considerations

When installing an air conditioning system, proper installation of the lineset is crucial for optimal performance. The lines must be correctly sized to match the specifications of the AC unit. If the lines are too small, they can restrict the flow of refrigerant, leading to inefficient cooling and potential damage to the compressor. Conversely, lines that are too large can result in unnecessary energy consumption. The lines should also be installed with minimal bends and kinks to avoid obstruction and reduce the risk of refrigerant leakage. Proper insulation is necessary to prevent heat gain or loss and ensure that the system operates efficiently throughout its lifespan.

Maintenance and Troubleshooting

Regular maintenance of the AC lineset is vital for the longevity and efficiency of the air conditioning system. Inspections should be conducted to check for signs of wear, corrosion, or damage to the lines. Leaks in the lineset can significantly impact the performance of the system, leading to reduced cooling capacity and increased energy consumption. It is essential to address any leaks promptly by repairing or replacing the affected sections of the lineset. Additionally, the insulation around the lines should be inspected and replaced if it becomes damaged or degraded. Regular maintenance helps in avoiding costly repairs and ensures that the system remains in good working condition.

Impact on System Efficiency

The efficiency of an air conditioning system is closely linked to the condition and installation of the lineset. Properly installed and maintained linesets contribute to the overall efficiency of the cooling system by ensuring that the refrigerant is transported effectively between the indoor and outdoor units. Efficient refrigerant flow reduces the workload on the compressor, leading to lower energy consumption and reduced utility bills. Conversely, issues with the lineset, such as leaks or improper insulation, can lead to increased energy consumption and reduced cooling performance. Ensuring that the lineset is in optimal condition is crucial for maintaining the efficiency and effectiveness of the air conditioning system.

Types of Lineset Materials

The choice of material for AC linesets can significantly affect the performance and durability of an air conditioning system. Copper is the most commonly used material due to its excellent thermal conductivity and flexibility. Copper linesets effectively transfer heat and refrigerant, which contributes to efficient system operation. Additionally, copper’s resistance to corrosion makes it a long-lasting choice. Alternatively, aluminum is another material used for linesets. Although aluminum is lighter and often less expensive than copper, it may offer a different thermal conductivity and durability level. Each material has its advantages and considerations, and the choice depends on various factors, including system requirements, environmental conditions, and budget constraints.

Environmental Impact and Recycling

The environmental impact of AC linesets extends beyond their initial use. When replacing or disposing of old linesets, proper recycling practices are essential to minimize environmental harm. Copper and aluminum can be recycled, reducing the need for new raw materials and conserving natural resources. Additionally, proper disposal of refrigerant and other components helps prevent environmental contamination. As air conditioning technology advances, new materials and methods for lineset production and recycling continue to emerge, aiming to improve sustainability and reduce environmental impact. By staying informed about recycling options and choosing environmentally friendly practices, homeowners and technicians can contribute to more sustainable air conditioning solutions.

The lineset is a critical component of an air conditioning system, playing a key role in the transfer of refrigerant and overall system efficiency. Proper installation, regular maintenance, and timely repairs are essential for ensuring the optimal performance of the lineset and, consequently, the entire cooling system. By understanding the role of AC linesets and addressing any issues promptly, homeowners can ensure that their air conditioning systems operate efficiently, providing reliable cooling and comfort throughout the year. Investing in the proper care and maintenance of the lineset contributes to the longevity and effectiveness of the air conditioning system.